1. Product introduction

ISG series vertical pipeline centrifugal pump (vertical centrifugal pump) is an excellent hydraulic model selected by our scientific and technical personnel in conjunction with domestic pump experts, which is ingeniously combined and designed on the basis of general vertical pumps using the performance parameters of IS type centrifugal pumps. At the same time, applicable hot water, high temperature, corrosion resistant chemical pumps and oil pumps are derived on the basis of ISG type according to the use temperature, media, etc. This series of products have the advantages of high efficiency, energy saving, low noise, reliable performance, etc. It meets the requirements of the latest JB/T53058-93 of the Ministry of Machinery. The products are designed and manufactured according to the international ISO2858 standard.

2. Product pictures

3. Scope of application

(1) ISG vertical pipeline centrifugal pump can transport clean water and liquids with physical properties similar to water. It is suitable for industrial and urban water supply and drainage, pressurized water supply for high-rise buildings, garden sprinkler irrigation, fire pressurization, long-distance transmission, HVAC refrigeration cycle, bathroom and other cold and warm water cycle pressurization and equipment supporting, with the operating temperature of T<80 ℃.

(2) IRG type hot water circulating pipe pump is suitable for pressurized circulating transmission of high-temperature hot water for metallurgical, chemical, textile, wood processing, paper making, hotels, bathrooms, hotels and other boilers, as well as urban housing heating circulating pumps, with the operating temperature below 120 ℃.

(3) IHG stainless steel chemical pipeline pump is suitable for conveying corrosive liquid medium without solid particles, and is widely used in petroleum, chemical industry, metallurgy, paper making, food, pharmacy, synthetic fiber and other departments. Its service condition is - 20 ° C ≤ temperature ≤ 120 ° C.

(4) YG type vertical explosion-proof oil pipeline pump is specially used to transport petroleum products, such as gasoline, kerosene, diesel, etc. The temperature of the conveyed medium is - 20 ℃~+120 ℃.

4. Product Features

ISG vertical pipeline centrifugal pump is a vertical structure, with the same inlet and outlet diameters, and located on the same centerline. It can be installed in the pipeline like a valve. It has a compact and beautiful appearance, small floor area, and low building investment. If it is equipped with a protective cover, it can be used outdoors. The impeller is directly installed on the extended shaft of the motor. The axial dimension is short, and the pump and motor bearings are reasonably configured, which can effectively balance the radial and axial loads generated by the pump operation, thus ensuring the smooth operation of the pump and low vibration noise. The installation and maintenance of instant noodles does not require dismantling the pipeline system. All rotor components can be extracted by removing the nuts of the pump coupling seat. The series and parallel operation mode of pumps can be adopted according to the use requirements, i.e. the flow and head. The pump can be installed vertically and horizontally according to the requirements of pipeline layout. The series has a flow range of 1.5~1600m3/h and a lift range of 5~125m. It is divided into basic type, shunt type, cutting type and other specifications.

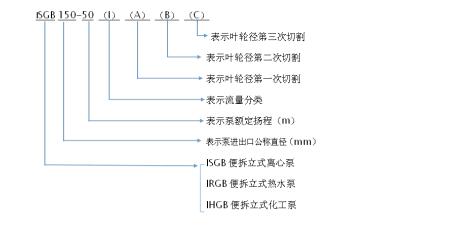

5. Model Meaning

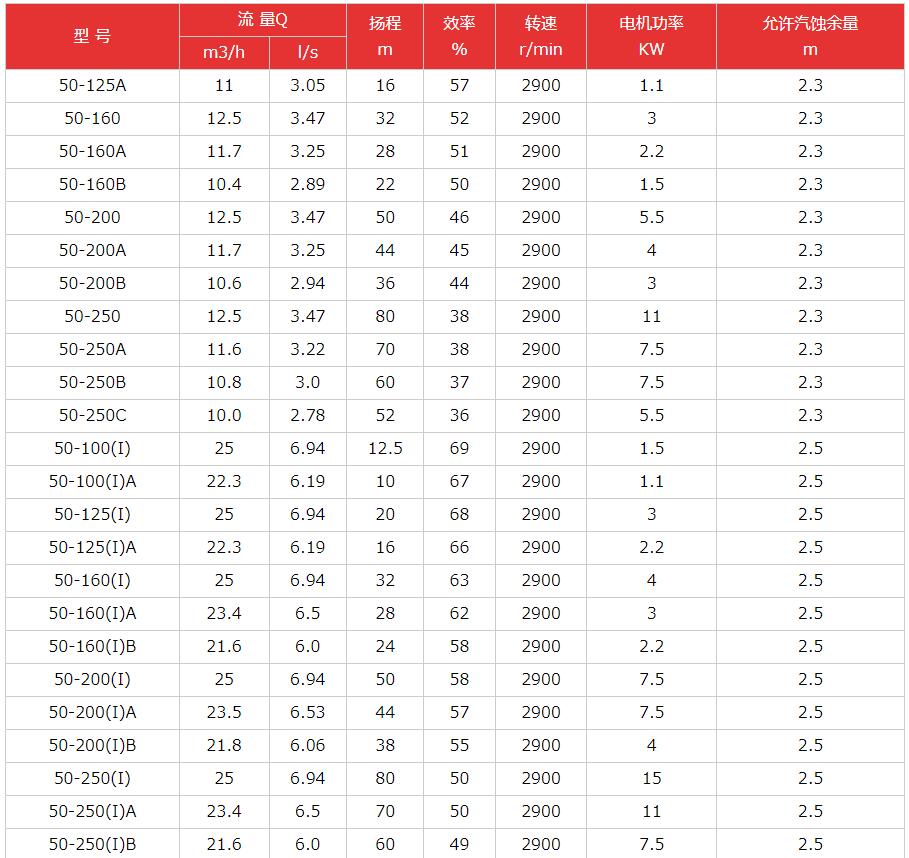

6. Specifications

7. Installation method

(1) Before installation, check whether the fasteners of the unit are loose and whether the flow passage of the pump body is blocked by foreign matters, so as to avoid damage to the impeller and pump body during the operation of the pump.

(2) During installation, the pipe weight shall not be added to the pump to avoid deformation of the pump.

(3) The foundation bolts must be tightened during installation to avoid the impact of vibration on pump performance during startup.

(4) For the convenience of maintenance and safety of use, a regulating valve is installed on the inlet and outlet pipelines of the pump and a pressure gauge is installed near the pump outlet to ensure the operation within the rated head and flow range, ensure the normal operation of the pump and increase the service life of the pump.

(5) After installation, move the motor sealing blade, and the impeller shall be free of friction sound or seizure, otherwise, the pump shall be disassembled to check the cause.

8. Precautions

(1) ISG vertical centrifugal pump is used for suction, and it shall be equipped with bottom valve, and the inlet pipeline shall not have too many bends, and there shall be no water and air leakage.

(2) Test whether the rotation direction of the motor is correct. The motor rotates clockwise when looking at the pump from the top of the motor. The test time should be short to avoid dry wear of the mechanical seal.

(3) The inlet pipe must be filled with liquid, and the pump is forbidden to operate for a long time under cavitation.

(4) When starting the pump, let the pump vent by loosening the vent screw on the pump head until a steady flow of liquid flows out of the vent hole, and then tighten the vent screw.

9. Frequently Asked Questions

(1) The water pump does not absorb water, which may be due to insufficient water injected into the pump.

(2) The insufficient flow of the water pump may be caused by the blockage of the water pump, wear of the impeller, insufficient speed, etc.

(3) Excessive pump power may be used beyond the rated flow.

(4) Noise and vibration may be caused by unstable pipeline support, gas mixed with liquid, bearing damage, etc.

10. Use needs

(1) Regularly check the pump performance (such as flow, lift, vibration, etc.) and make records. The maintenance items and the interval time between each maintenance depend on the working conditions and operating conditions of the pump.

(2) After the pump has been running for a long time, if the noise and vibration of the unit increase due to mechanical wear, it shall be stopped for inspection, and the wearing parts shall be replaced if necessary,

(3) It is prohibited to run the motor for a long time with excessive current when the pump is running at large flow.

(4) The medium conveyed by the pump shall not contain air or gas, otherwise, the flow and lift of the pump will not be measured accurately, and the parts will be damaged by grinding.

(5) The suction pipe of the pump shall be as short as possible, the pipe diameter shall be greater than or equal to the diameter of the suction inlet of the pump, and the bending radius of the suction pipe of the pump shall be as large as possible.

ISG Vertical Pipeline Centrifugal Pump: Complete Guide

The ISG Vertical Pipeline Centrifugal Pump is a single-stage, energy-efficient vertical inline pump designed for modern water supply, HVAC, fire protection, and industrial circulation systems. Its compact vertical structure, high hydraulic efficiency, and quiet operation make it ideal for applications requiring reliable performance and space-saving installation.

This guide covers quality control, inspection reports, upgrade and maintenance planning, and user guidance to provide professionals with detailed insights into the pump’s performance, longevity, and operational best practices.

The ISG Vertical Pipeline Pump is designed according to international ISO and DIN standards, ensuring consistent quality and performance across global installations.

Vertical inline design: Saves floor space and simplifies integration.

Single-stage operation: High efficiency for clean water and low-viscosity fluids.

Energy-saving motor options: Compatible with IE2/IE3 high-efficiency motors.

Low noise and vibration: Suitable for commercial and industrial environments.

Durable construction: Corrosion-resistant materials such as stainless steel or cast iron.

| Parameter | Range |

|---|---|

| Flow capacity | 1.5 – 1200 m3/h |

| Head | 5 – 140 m |

| Power | 0.55 – 250 kW |

| Operating temperature | -20°C to +120°C |

| Materials | Cast iron, stainless steel, bronze |

| Sealing | Mechanical seal, double seal optional |

| Installation | Vertical inline |

Quality assurance is a critical component of ISG pump manufacturing, ensuring reliability and longevity.

ISO 9001 certified manufacturing: All components produced under strict quality guidelines.

Precision casting and machining: Ensures hydraulic efficiency and tight tolerances.

Material verification: Corrosion-resistant metals tested for hardness, tensile strength, and chemical composition.

Hydraulic testing: Verifies flow rate, head, and efficiency under rated conditions.

Noise and vibration testing: Ensures compliance with operational comfort standards.

Mechanical integrity: Housing, impeller, and shaft inspected for structural stability.

Sealing performance: Mechanical seals tested for leakage prevention under high pressure.

Each ISG pump is accompanied by a detailed quality inspection report, providing traceable documentation for buyers and engineers.

| Report Section | Details |

|---|---|

| Material Certification | Confirms material composition, mechanical properties, and corrosion resistance |

| Hydraulic Test Data | Flow, head, efficiency, NPSH (Net Positive Suction Head) values |

| Vibration & Noise Levels | Measured decibel levels and vibration frequency under load |

| Electrical Test Report | Motor insulation resistance, voltage, current, and efficiency |

| Final Inspection Checklist | Visual inspection, dimensional verification, seal test, and functional test |

These reports help clients verify compliance with project specifications, regulatory standards, and international energy efficiency guidelines.

Maintaining ISG pumps is essential for long-term operational reliability and energy efficiency. An upgrade and maintenance plan can significantly extend pump service life and reduce downtime.

Daily: Check for unusual noise, vibration, or leaks.

Weekly: Inspect mechanical seals, lubrication levels, and pipe connections.

Monthly: Clean pump inlet strainer and external surfaces.

| Task | Frequency | Notes |

|---|---|---|

| Bearing lubrication | Every 3–6 months | Use manufacturer-approved grease |

| Impeller cleaning | Every 6–12 months | Prevent blockage and cavitation |

| Mechanical seal inspection | Every 12 months | Replace worn seals promptly |

| Motor inspection | Every 12 months | Check insulation resistance and current draw |

| Full pump overhaul | Every 2–3 years | Replace bearings, seals, and worn parts |

Motor efficiency upgrade: Replace standard motors with IE3 high-efficiency options.

Seal enhancement: Install double mechanical seals for higher pressure applications.

Material upgrade: Stainless steel or coated components for corrosive liquids.

Control system integration: Add VFD (Variable Frequency Drive) for energy savings and flow optimization.

Proper operation is essential for safe and efficient pump performance.

Foundation: Place pump on a rigid, vibration-free base.

Alignment: Ensure vertical inline alignment with the pipeline.

Piping: Install suction and discharge valves, strainer, and flexible couplings.

Electrical Connection: Ensure motor wiring follows local safety standards and grounding requirements.

Prime the pump completely before starting.

Open suction and discharge valves gradually.

Monitor motor current, vibration, and noise during initial operation.

Verify system pressure and flow against design parameters.

Avoid dry running, which can damage mechanical seals.

Maintain proper water quality to prevent scaling, corrosion, or cavitation.

Monitor temperature and lubrication regularly.

Gradually adjust flow and pressure to prevent hydraulic shock.

Close discharge valve slowly to prevent pressure spikes.

Turn off motor and allow pump to cool.

Inspect pump for leaks, vibration, or unusual noise.

Record operational data for future reference.

Even high-quality ISG pumps may encounter operational issues.

| Problem | Possible Cause | Recommended Action |

|---|---|---|

| Low flow | Clogged inlet, wrong pump size | Clean inlet, check design parameters |

| Vibration | Shaft misalignment, unbalanced impeller | Realign, balance impeller |

| Overheating | Bearing wear, low lubrication, overload | Lubricate, replace bearings, reduce load |

| Leakage | Worn mechanical seal, improper installation | Replace seal, reinstall correctly |

| Motor overload | Electrical issues, pump blockage | Inspect motor, check electrical connection, clear blockage |

ISG pumps are designed to meet modern energy-saving requirements.

Optimized impeller and casing design reduces hydraulic losses.

High-efficiency motors reduce electricity consumption.

Variable frequency drive (VFD) integration allows flow adjustment according to demand.

Lower operating costs.

Reduced environmental footprint.

Extended service life due to optimized operation.

Compliance with international energy standards (IEC, ISO).

The ISG Vertical Pipeline Centrifugal Pump is widely used across industries:

Municipal water supply – booster pumps, pressure regulation.

HVAC systems – chilled water circulation, cooling towers.

Fire protection – high-pressure fire-fighting systems.

Industrial fluid transfer – clean water, low-viscosity liquids.

Commercial buildings – water booster for high-rise systems.

Compact vertical inline design saves floor space.

High hydraulic efficiency for low energy consumption.

Durable materials for corrosion and wear resistance.

Low noise and vibration suitable for commercial and industrial environments.

Wide application range with flexible maintenance options.

The ISG Vertical Pipeline Centrifugal Pump is a high-efficiency, compact inline pump designed for vertical installation in water supply, HVAC, fire protection, and industrial circulation systems. Built with durable materials, precision hydraulics, and optional energy-saving motors, it ensures long service life, low noise, and stable operation. Each pump comes with a detailed quality inspection report and supports upgrade and maintenance plans for optimal performance in industrial, commercial, and municipal applications.

The ISG Vertical Pipeline Centrifugal Pump combines quality control, energy efficiency, and operational reliability for modern water and fluid handling systems. With detailed inspection reports, upgrade plans, and user guidelines, the pump ensures safety, performance, and cost savings.

This guide equips engineers, buyers, and operators with practical knowledge for installation, maintenance, and troubleshooting, making the ISG pump a trusted choice for industrial and commercial projects worldwide.

Phone:+86 15868545868/+8618968868555

whatsapp:+86 15868545868/+8618968868555

Email:haiwan@haiwanpump.cn

Add:Meiao Street, Qiaoxia Town, Yongjia County Wenzhou City, Zhejiang, China

Copyright ? 2025 Zhejiang Haiwan Pump Industry Co., Ltd.